Bubble film and pearl cotton cutting machine current location:home page > Bubble film and pearl cotton cutting machine

| |

|

|

Basic operating steps:

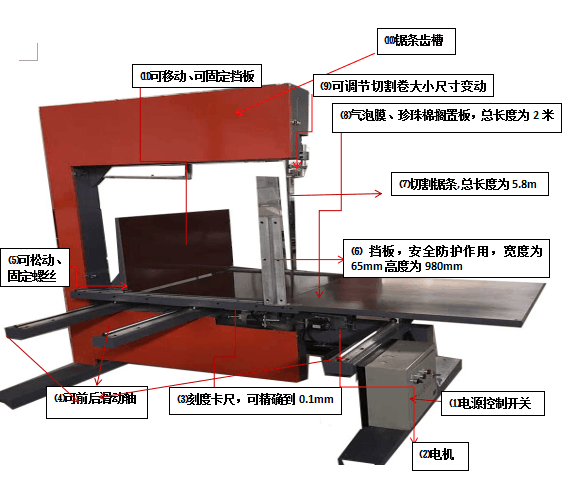

1. At the position where the screws can be loosened and fixed (as shown in Figure 5), adjust the size of the product to be cut, such as 300mm/500mm/800mm, and fix the size.

2. Slide the laydown plate on the sliding shaft (as shown at position (4)) open and place the product to be cut.

3. The saw blade (as shown in position (7) in the figure) can cut a product diameter of 950mm, and the size of the cutting coil can be adjusted by a variable device (as shown in position (9) in the figure) to change the product to be cut.

4. Turn on the machine power control box (as shown in Figure ⑴), turn on the air switch, and close the power control switch box.

5. Loosen the saw blade (detached from the main drive pulley)

6. Turn on the green button on the outside of the power control switch box, and the motor will start running. (It is necessary to pay attention to whether the motor blades rotate clockwise, as counterclockwise will damage the saw blade.)

7. The operator stands at the protective baffle (as shown in the figure (6)), pushes the sliding shaft shelf plate to the saw blade for cutting (the protective baffle can be pushed)

8. After the cutting is completed, turn off the red button on the outside of the power control switch box (as shown in Figure ⑴), and the machine will stop running.

9. When cutting is not required, it is necessary to turn off the independent switch of the power switch control box (as shown in Figure ⑴).

Precautions: When adjusting the cutting size regulator, the green button (green switch) on the power control switch box (as shown in the figure at position ⑴) must be in the off state.

Attention should be paid to the rotation direction of the motor, and the motor blades should be in a clockwise direction. (As shown in position ⑵ in the figure), reverse operation can easily cause the cutting saw blade to break, requiring replacement of the saw blade.

COPYRIGHT © 2019 Rui'an Hengtuo Machinery Co., Ltd Copyright map

Main products:Bubble film machine、Wrapping film machine、Granulators